Movable Rip Saw

MRS-450M+Rip One

Tags :

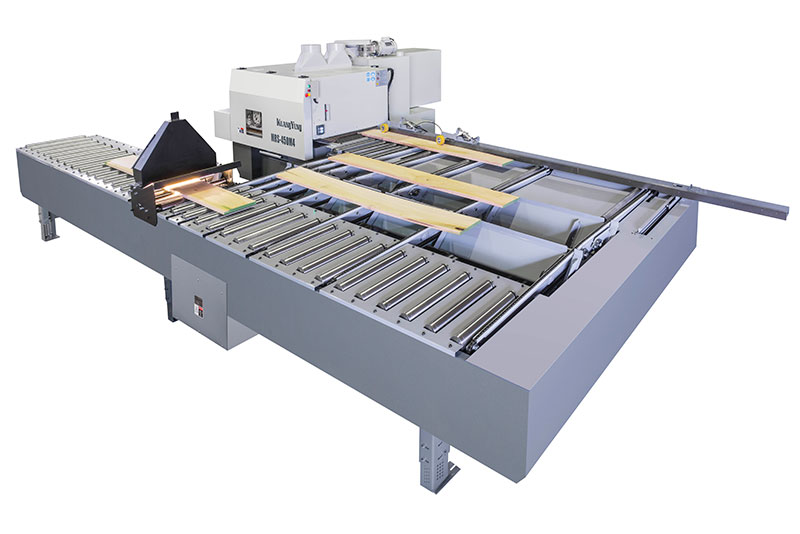

Movable Rip Saw MRS-450M + Rip One is engineered for manufacturers who demand next-level accuracy and efficiency. As part of our Moving Blade Rip Saws and Movable Blade Rip Saws lineup, this model integrates Scanner Rip Saw capability to capture the full contour of every board—making it one of the most precise and productive Wood Processing Machines available.

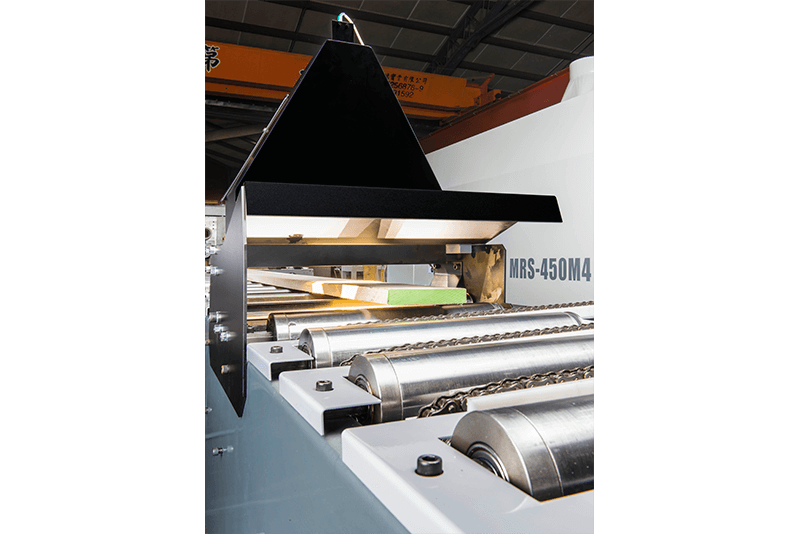

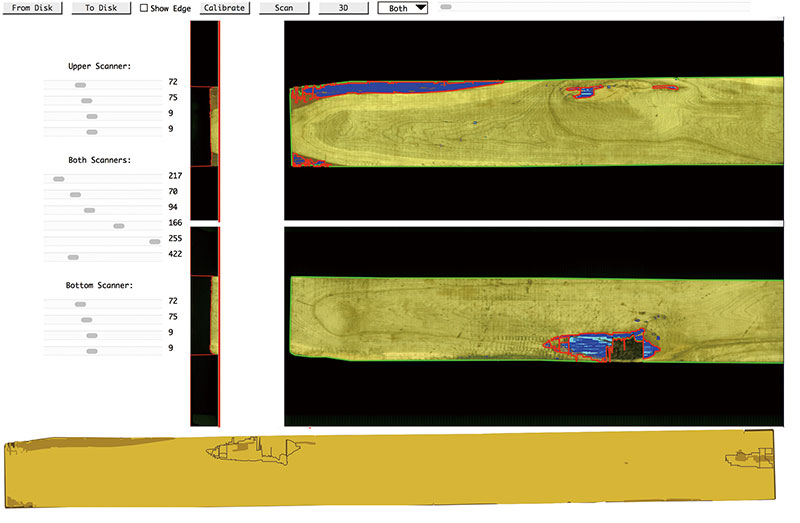

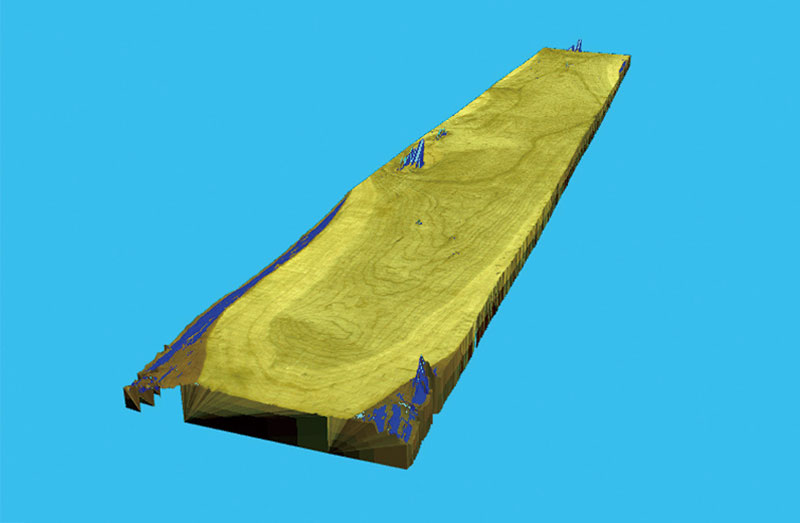

With ultra-high-resolution dual cameras and intelligent defect recognition, this Optimizing Movable Rip Saw operates as a true Scanner Rip Saw, analyzing thickness, bark, knots, and cracks in real time. By combining the adaptability of a CNC Wood Cutting Machine with the throughput of an Automatic Saw Machine, Rip One maximizes usable lumber, reduces waste, and increases yield by 2–3% compared to conventional systems.

- Consistent, high-quality performance for modern Sawmill and Wood Mills operations

- Top and bottom 2 MP HD cameras capturing data at 100 fps

- Processes 7–9 3 m boards per minute for maximum productivity

- Advanced board profiling for thickness, bark, knots, cracks, and defects (Scanner Rip Saw)

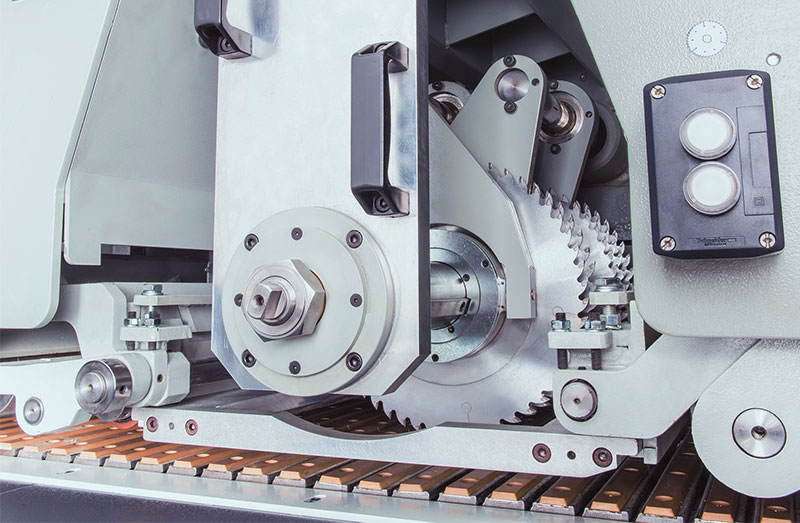

- Automatic Fence Skew increases yield by 2–3% on bent or irregular boards

Features of Rip One System

- Powered rollers infeed system makes it convenient to load wood. In case a malfunction occurs, it is easy to move wood away.

- ”U” shaped wood feed route in combination with the rear storage area, allowing for storing 4 pieces of wood. The operator position is safe without risk caused by wood kickback. Flexible manpower arrangement allows one operator to perform both workpiece infeed and collection jobs.

- With its powerful software operation, the system not only can accurately scan 3D sizes of wood, but also has the capability to identify side defect, bark, wood knot and crack.

- The computer provides size setting, optimization and simulation. Also, available to set up file management with different job sheets according to customers and tree species. Reports including throughput,

Specification

| MRS-450M+Rip One | |

|---|---|

| Max. cutting thickness | 12" / 75 mm , 14" / 100 mm |

| Number of movable saws | 3, Optional: 4 |

| Max. material width of pass-through | 875 mm |

| Max. cutting width | 450 mm |

| Min. material length | 610 mm |

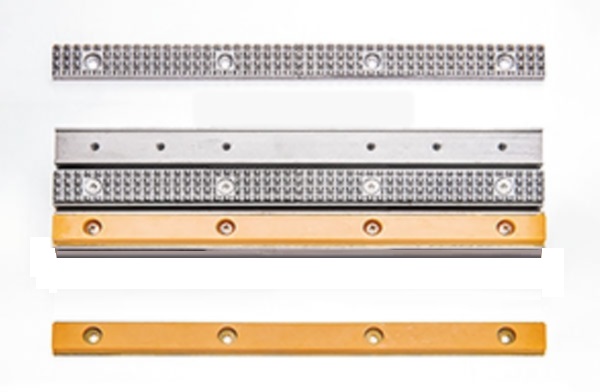

| Max. sawblade diameter | Ø355 mm (14") |

| Min. sawblade diameter | Ø305 mm (12") |

| Sawblade bore | Ø90 mm |

| Saw arbor diameter | Ø70 mm |

| Saw arbor speed | 4200 R.P.M. (50Hz) / 4500 R.P.M. (60Hz) |

| Saw arbor motor | 50, 60, 75, 100 or 125 HP |

| Feed motor | 5 HP |

| Variable feed speed | 8 ~ 60 m/min |

*We reserve the right to amend any of the above specifications without prior notice.

Comparison

| MRS-340M+Skew | MRS-450M+Rip One | MRS-610+Quick Rip | |

|---|---|---|---|

| Max. cutting thickness (with short stock cutting device) |

12" - 60mm / 14" - 80mm | 12" - 75mm / 14" - 100mm | 12" - 60mm / 14" - 100mm |

| Number of movable saws | 3, Optional: 4 | ||

| Max. material width of pass-through | 650mm(25.6") | 875 mm | 900 mm |

| Max. cutting width | 340mm (13.4") | 450 mm | 610 mm |

| Min. material length | 1.1M(3.6') | 610mm | |

| Max. sawblade diameter | Ø355mm(14") | ||

| Min. sawblade diameter | Ø305mm(12") | ||

| Sawblade bore | Ø90mm | ||

| Saw arbor diameter | Ø70mm | ||

| Saw arbor speed | 14" - 3800rpm (50Hz,60Hz) | 4200 rpm (50Hz) | |

| 12" - 4200rpm (50Hz), 4500rpm (60Hz) | 4500 rpm (60Hz) | ||

| Saw arbor motor | 30HP,40HP,50HP,60HP | 50,60,75,100 or 125 HP | |

| Feed motor | 3HP | 5 HP | |

| Variable feed speed | 12 ~ 40 m/min | 8~60 m/min | |

*We reserve the right to amend any of the above specifications without prior notice.