Multiple Rip Saw

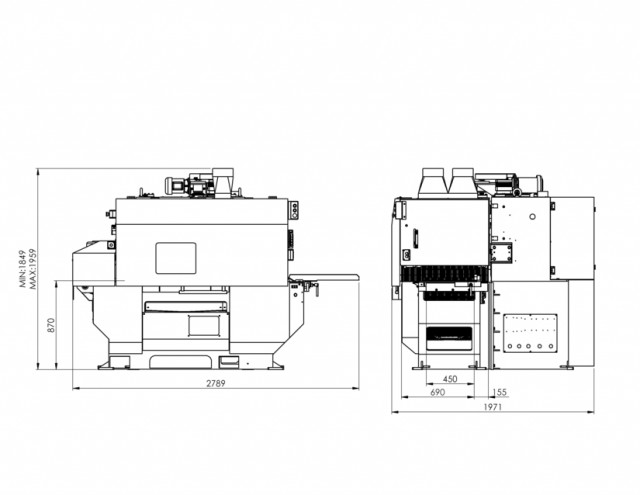

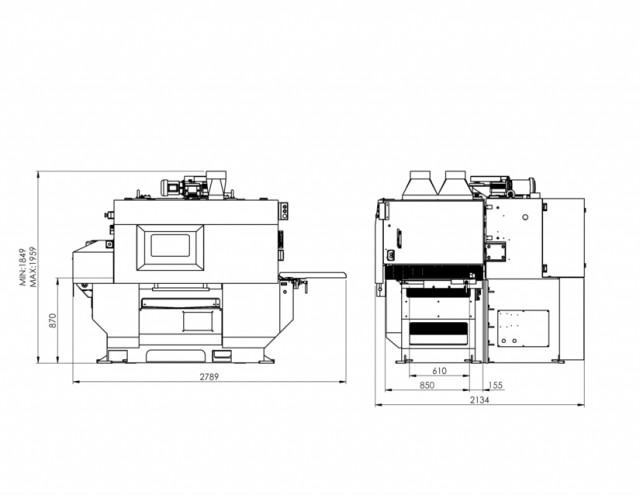

MRS-340

Tags :

Multiple

Optimizing

Advanced Multiple Rip Saw

Your Prime Choice Mutiple Rip Saw

Main Features

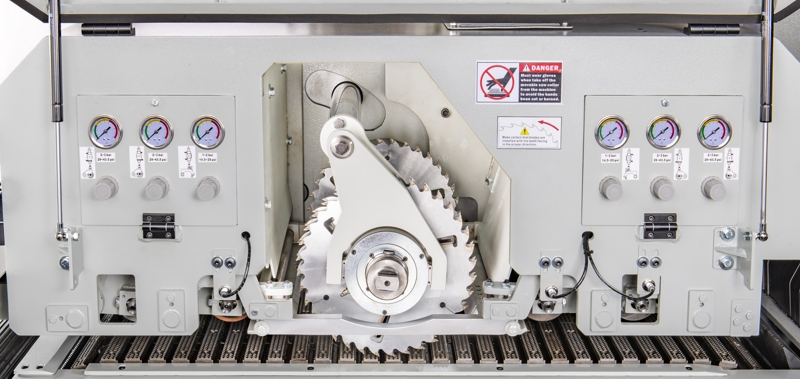

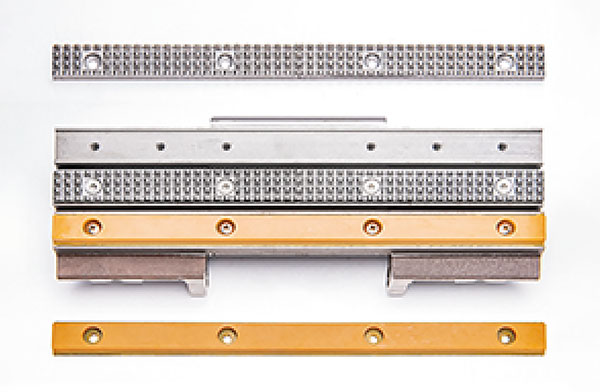

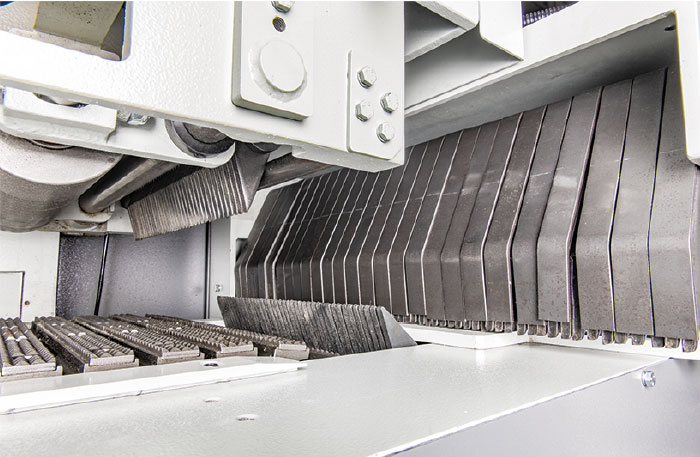

- Mihanna cast iron seamless chain slats paired with precision double-V rails.

- Saw arbor made from imported Japanese nickel-chromium-molybdenum alloy, heat-treated.

- Roller holders designed with pneumatic pressure material design.

These features enable direct panel joining after sawing.

- With 20 years of development experience and over a hundred units sold since 2004, it is now a mature product.

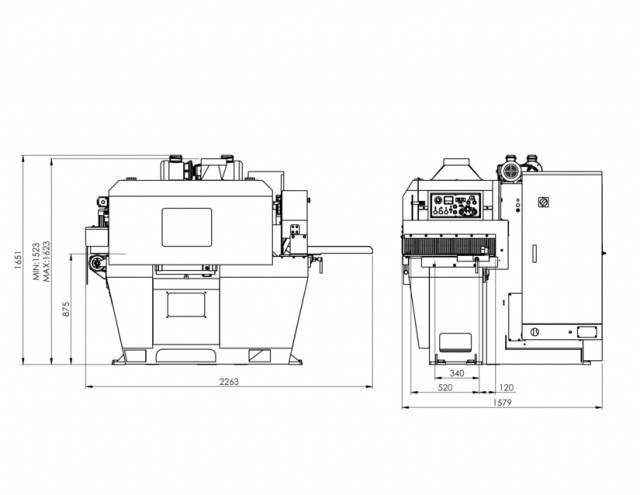

Specification

| MRS-340 | |

|---|---|

| Max. cutting thickness (Ø14) | 110 mm |

| Max. cutting thickness(Ø12) | 75 mm |

| Max. cutting width | 340 mm (13.4") |

| Min. material length (standard) | 550 mm (22") |

| Min. material length (with short stock cutting device) | 400 mm (15.8”) |

| Max. sawblade diameter | Ø355 mm (14") |

| Min. sawblade diameter | Ø305 mm (12") |

| Sawblade bore | Ø55mm |

| Saw arbor diameter | Ø70mm |

| Saw arbor speed | 3800 rpm (50,60 HP) |

| Pressure roll motor | 0.5 HP |

| Saw arbor motor | 30, 40 ,50 ,60 HP |

| Feed motor | 3 HP |

| Dust hood dia. | Ø200 mm (8") x 2 / Ø100 mm (4") x 1 |

*We reserve the right to amend any of the above specifications without prior notice.

Comparison

*We reserve the right to amend any of the above specifications without prior notice.