Movable Rip Saw

MRS-450M (Joystick)

Tags :

Optimizing

Movable

Joystick Semi-Optimizing Movable Rip Saw

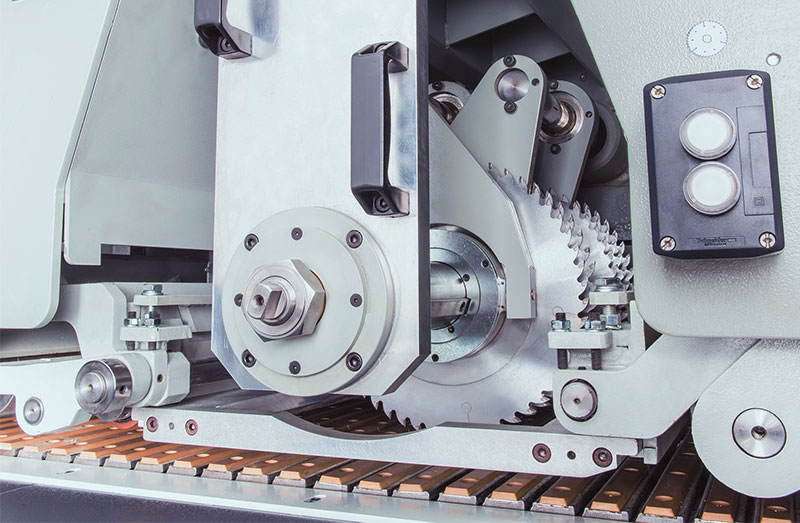

The MRS-450M combines the precision of a woodworking CNC machine with the efficiency of a cut-off saw. Featuring an intuitive IPC, controller, and responsive touch panel, it offers easy operation and optimized rip sawing configurations for superior performance, making it perfect for high-demand woodworking applications requiring speed and accuracy.

Main Features

- Choice of 1-6 movable blades

- Extra large 450mm cutting width

- Optimizing cut function

Available Models

- Employs a touch screen for easy operation and learning.

- All functions displayed on the screen.

- The instructional cutting width setting provides optimum system calculation, made easier with icons and graphic display.

- Convenient troubleshooting is achieved through the computer display.

- The movable rip saw blade is driven by a servomotor, featuring fast movement and outstanding positioning accuracy.

Features Of Movable Rip Saw

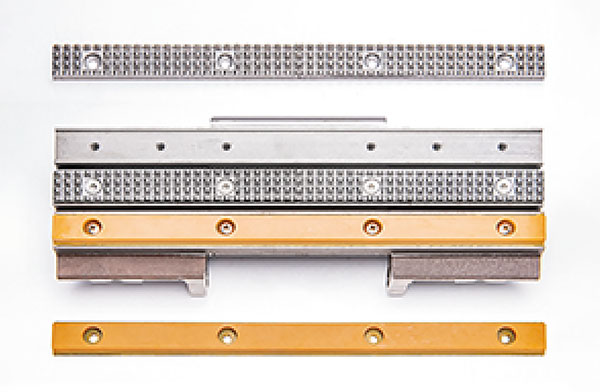

- By applying Multi-Axis (Max: 6 axes) moving saw design, different widths of products can be completed in one cut.

- Wider cutting width (Max: 610/450 mm) with powerful spindle motor and high speed feeding chain.

- Wide cutting width extends application range, which provides the best solution for high efficiency and cutting optimization, especially for high quality timber

Specification

| MRS-450M | |

|---|---|

| Max. cutting thickness of movable saw | 60 mm (12" blade) , 100 mm (14" blade) |

| Number of movable saws | 3, Optional: 4 |

| Max. material width of pass-through | 750 mm |

| Max. cutting width | 450 mm |

| Min. material length | 610 mm |

| Max. sawblade diameter | Ø355 mm (14") |

| Min. sawblade diameter | Ø305 mm (12") |

| Sawblade bore | Ø90 mm |

| Saw arbor diameter | Ø70 mm |

| Saw arbor speed | 4200 rpm (50HZ) / 4500 rpm (60HZ) |

| Saw arbor motor | 50 , 60 , 75 , 100 or 125HP |

| Feed motor | 5 HP |

| Variable feed speed | 8-60 M/min |

*We reserve the right to amend any of the above specifications without prior notice.

Comparison

| MRS-450M | MRS-610M | |

|---|---|---|

| Max. cutting thickness | 12" / 60 mm, 14" / 100 mm | |

| Number of movable saws | 3, Optional: 4 | |

| Max. material width of pass-through | 750 mm | 900 mm |

| Max. cutting width | 450 mm | 610 mm |

| Min. material length | 610 mm | |

| Max. sawblade diameter | Ø355 mm (14") | |

| Min. sawblade diameter | Ø305 mm (12") | |

| Sawblade bore | Ø90 mm | |

| Saw arbor diameter | Ø70 mm | |

| Saw arbor speed | 4200 rpm (50HZ) / 4500 rpm (60HZ) | |

| Saw arbor motor | 50, 60, 75, 100 or 125HP | |

| Feed motor | 5 HP | |

| Variable feed speed | 8~60 M/min | |

*We reserve the right to amend any of the above specifications without prior notice.